Acoustic Laboratories for BSR noise analysis

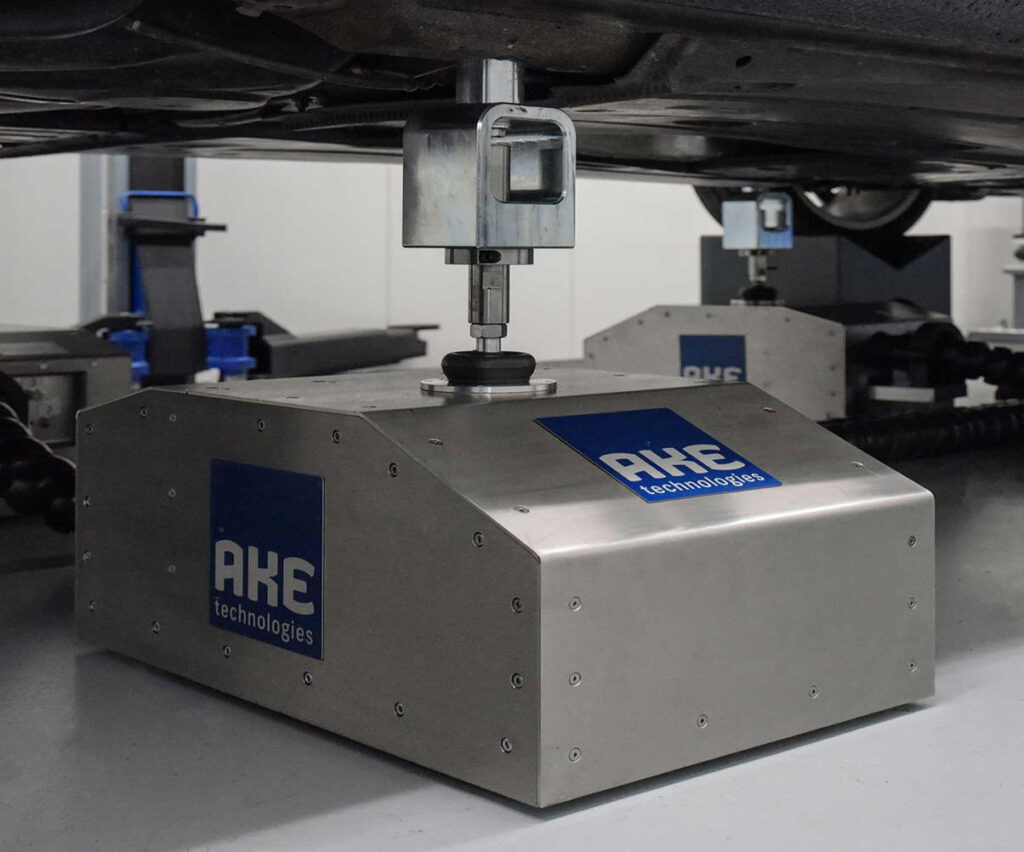

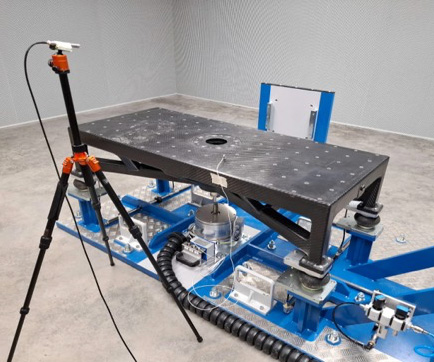

In cooperation with the shaker specialists of AKE technologies, TStech offers the turnkey supply of acoustic test facilities with integrated shaker test systems which are tailored to the specific requirements of BSR tesing:

- high-performance acoustic lining

- ultra-low background noise levels

- silent lighting and HVAC system

- exceptionally quiet shaker systems without disruptive operating noise

The integration of a comprehensive BSR noise test & analysis strategy into the product development cycle gives manufacturers a competitive advantage due to improved product quality and reliability. Products that are free from annoying BSR noise issues also lead to measurably higher customer satisfaction while also reducing warranty costs.

Investments in test facilities for R&D activities or quality control inspections lead to innovative and improved products which generate significant returns and ensure long-term economic growth.

In particular the exceptionally quiet “mobility of the future” with electrically powered or autonomous vehicles is characterised by customer demands for a superior sound quality of vehicle interiors, making acoustic optimization indispensable. The demand for acoustic comfort is also growing in commercial vehicles, trains, and aircraft. AKE vehicle and component shakers are among the quietest systems on the market and utilize real road profiles or synthetic data to generate load profiles with high accuracy. This allows unwanted noise to be reproduced, identified, analysed, and eliminated under controlled laboratory conditions at all stages of product development cycle.

The main causes of unwanted BSR noises are weaknesses in the vehicle structure due to insufficient stiffness or damping, unfavorable material pairings, or contact points resulting from component geometry or installation position. To investigate these problems during the early stages of the vehicle development process and to avoid them entirely during production, laboratory-based investigations are essential – both on component or sub-system level as well as for the complete vehicle.

First, the actual vehicle movements are recorded during a real test drive using acceleration sensors attached to the vehicle body or the components under test. Then a so-called drive file is generated from this data. The recorded excitation signals can then be fed into the shaker test system and thus replicate the real-world vibration excitation in the laboratory.

According to market surveys, BSR noises are among the most important customer concern in cars after 3 months of ownership. But what is “BSR” anyway?

“Buzz”: describes noises that are emitted by a single vibrating structure or an electrical component. Electrical buzzing sounds are mainly caused by electromagnetic interference.

“Squeak”: squeaking noises usually originate from frictional movement between two parts at their point of contact. A classic example is squeaking rubber seals when opening or closing windows which is caused by the so-called stick-slip effect, when adhesive and sliding forces between the two materials alternate.

“Rattle”: noise that is caused when two surfaces collide or strike each other repeatedly. The main cause for rattle noises are structural deficiencies and poor geometrical design.

Acoustic and Combined climatic-acoustic Test Facilities

Acoustic chambers in according to ISO 3745 or ISO 3744 in combination with the noiseless AKE shaker systems, provide the optimal environment for BSR noise testing. Combined climatic-acoustic laboratories are fitted with an HVAC system, thus enabling BSR testing under varying environmental conditions. The shaker actuators are corrosion- and climate-resistant and operate quietly and reliably even in continuous operation.

Mobile Chamber Design

Due to the structural changes in the automotive industry, many companies face lack of long-term planning reliability or use temporary rental locations for R&D tasks. Hence a trend towards mobile test systems has emerged that are not tied to a specific location. TStech has developed a range of customized acoustic test chambers that can be shifted to various locations inside a building (e.g. parked in a storage location when not in use) or moved to a new building if required. AKE shaker test systems can be integrated in these mobile chambers, too.